Highlights

- Functional, ergonomic machine design with compact footprint

- Integrated workpiece handling to ensure minimal non-productive times

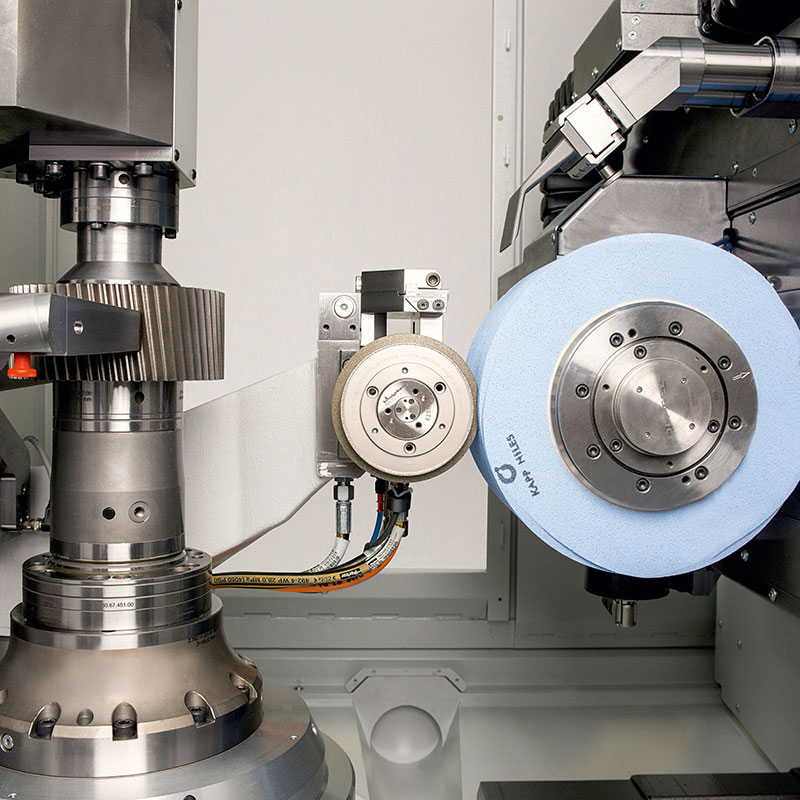

- Application of dressable tools with high cutting speeds

- Additional functionalities through application-specific alignment and measuring devices

- Intuitive control through clearly guided operating concept

max. | max. | module | max. | max. | |

| 350 | 700* | 0.5 - 6 | 400 | ±45 |

* depends on the loading system

Machine concept

The KNG 350 expert is based on a compact, set-up-optimised machine concept and is intended for use in medium and large-scale series production of external geared components.

The integrated workpiece handling ensures short non-productive times and can handle both bored parts and shafts.

The new functional and ergonomic machine design paired with the innovative user- friendly interface KN grind supports the user during set-up and optimisation of grinding projects.

High-performance technology options combined with application-specific aligning and measuring functions enable maximum precision and surface qualities on the workpiece. The NC-controlled aligning device adapts automatically to different workpieces.