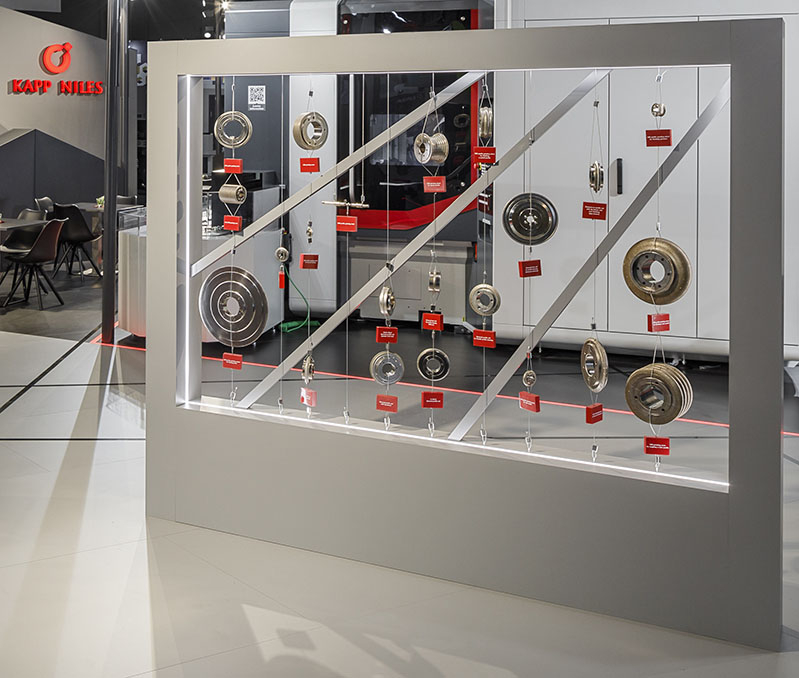

Highlights

Dressing Tools

- Long service life due to highly wear-resistant CVD inserts

- Highest profile precision possible

- Repeatedly regrindable and replateable tools

- High-precision design available for e-mobility applications

- Optional use of RFID data storage carriers for optimisation of set-up process or for the storage of all process-relevant information

KAPP NILES manufactures diamond profile rolls as well as diamond form rolls for generating grinding with ceramic-bonded worms. In large-scale production, the dressing of the worms can also be carried out with highly productive multi-ribbed diamond profile rolls.

For profile grinding, diamond form rolls in sintered design are offered for profiling dressable profile grinding wheels. Diamond dressing gears for profiling dressable honing rings complete the portfolio.

Profile grinding

Diamond form rolls

Diamond form rolls are available in sintered design for profiling dressable profile grinding wheels. In addition to the economic version with natural diamond, these are also offered as a long-life tool with handset CVD diamond. It is possible to reground these tools several times and they are characterised by a long life time.

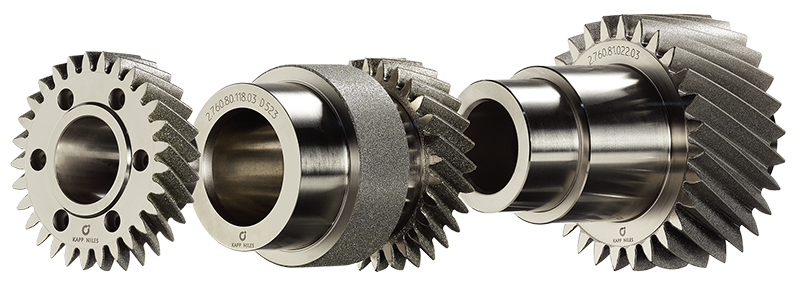

Generating grinding

Diamond profile rolls, diamond form rolls and multi-ribbed diamond profile rolls

Our portfolio includes workpiece-specific dressing rolls for dressing of ceramic-bonded worms as well as dressing rolls for flexible or topological dressing.

The dressing tools are used for generating grinding with natural entanglement and topological generating grinding with influenceable bias.

Multi-ribbed diamond profile rolls are also available for fast and efficient dressing. They are produced in galvanically negative design for a wide range of modules and rib numbers.

For serial production, an integrated tip dresser is used for defined grinding of the gear root area. Dressing rolls without tip dresser are also part of our portfolio.

The dressing tools for fine and polishing grinding - used in electromobility - are highprecision designed. The special feature of such a dressing roll is, in addition to the reference surface optimisation, the reworking of the diamond grains after the coating of the dressing roll base body.

Highlights

Grinding Tools

- Worldwide replating close to the customer

- Application-specific design and manufacturing

- Maximum level of quality and several decades of experience

KAPP NILES manufactures non-dressable, electroplated single-layer CBN tools for hard and soft finishing of gears and profiles. Our tools have been among the top products worldwide for decades. They are used when the highest demands are made on quality, performance and economy.

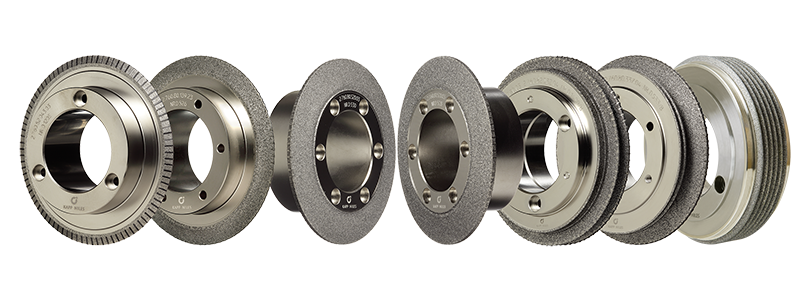

CBN profile grinding wheels

CBN profile grinding wheels are available in single or multi-ribbed roughing and finishing design and are used for grinding of :

- External and internal gears in automotive (passenger car, commercial vehicle) and aircraft industry

- Radial, screw, rotor and worm profile wheels

- High speed grinding of profiles and gears

- Plunge grinding, abrasive cutting and cylindrical grinding