Meet us at IMTS in Chicago / USA

09. - 14. September 2024 | Chicago USA | North building, Level 3 , Booth 237024

The perfect interaction between machine, tool and technology enables the precise machining to a thousandth millimetre and up to a diameter of eight metres.

Each system solution is individually optimised for customer requirements and serviced by us throughout its life cycle. Highly accurate measuring equipment complements the comprehensive product range to ensure the required quality.

KAPP NILES supports efficient and stable processes with innovative services and digital solutions.

Our team is looking forward to presenting our range of solutions, which can be perfectly tailored to your requirements, face to face.

We look forward to your visit and wish you an interesting and successful time at the IMTS in Chicago.

KNM 4X

Analytical measuring machines for small and medium-sized workpieces

Highlights

- Innovative quick change clamping system for reduction of non-productive times

- Compact design and quick measuring procedure

- Manually adjustable, permanently mounted tailstock with flexible clamping force adjustment to avoid the use of drivers

- Intuitive operator-friendly guidance through measurement and evaluation software KN inspect

Find out more about low-noise gears for electric drives with integrated waviness analysis on KAPP NILES measuring machines.

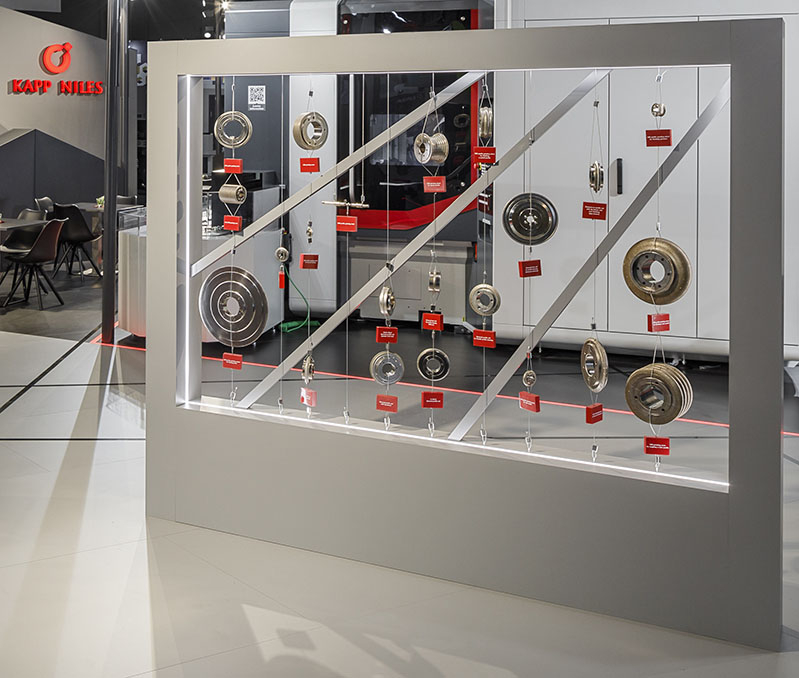

TOOLS

Dressing and Grinding Tools

Highlights

Dressing Tools

- Long service life due to highly wear-resistant CVD inserts

- Highest profile precision possible

- Repeatedly regrindable and replateable tools

- High-precision design available for e-mobility applications

- Optional use of RFID data storage carriers for optimisation of set-up process or for the storage of all process-relevant information

KAPP NILES manufactures diamond profile rolls as well as diamond form rolls for generating grinding with ceramic-bonded worms. In large-scale production, the dressing of the worms can also be carried out with highly productive multi-ribbed diamond profile rolls.

For profile grinding, diamond form rolls in sintered design are offered for profiling dressable profile grinding wheels. Diamond dressing gears for profiling dressable honing rings complete the portfolio.

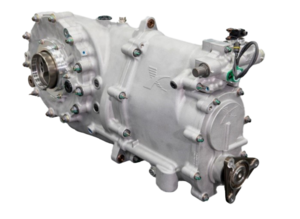

Xtrac | KAPP NILES

P1334 NASCAR Transaxle

Discover the innovative P1334 NASCAR Transaxle. The five-speed manual sequential change transaxle, including a variable preload differential is used in conjunction with independent rear suspension and 18 inch diameter wheels. The concept of moving the transmission to the rear of the Next Gen car was to improve driver safety, allowing the driver’s seat to be mounted closer to the centreline of the chassis.